Table of Contents

Manufacture of Sulfuric Acid (H2SO4):

Sulfuric acid is the most important of all the acids. It plays a vital role in the industrial development and hence the economy of a country. As a matter of fact, it is referred to as the king of all chemicals. Sulfuric Acid is present in certain mineral springs and is produced as a result of the interaction of water on sulfides like iron pyrites.

2FeS2 + 2H2O + 7O2 ——–> 2FeSO4 + 2H2SO4

Sulfuric acid is obtained on a commercial scale by the following two methods- lead chamber process and contact process.

Lead Chamber Process:

This is an old process of manufacturing sulfuric acid.

Theory of lead chamber process– The theory underlying lead chamber process is as under-

(a) Production of sulfur dioxide- It is produced by burning sulfur powder or iron pyrites in excess of air.

S + O2 ——> SO2

4FeS2 + 11O2 ———> 2Fe2O3 + 8SO2

(b) Oxidation of sulfur dioxide to sulfur trioxide- SO2 is oxidized to SO3 by nitrogen dioxide. Nitric oxide so formed combines with oxygen of the air to give nitrogen dioxide.

SO2 + NO2 ——-> SO3 + NO

2NO + O2 ——–> 2NO2

(c) Conversion of sulfur trioxide into sulfuric acid- Sulfur trioxide is dissolved in water to yield sulfuric acid.

SO3 + H2O ——-> H2SO4

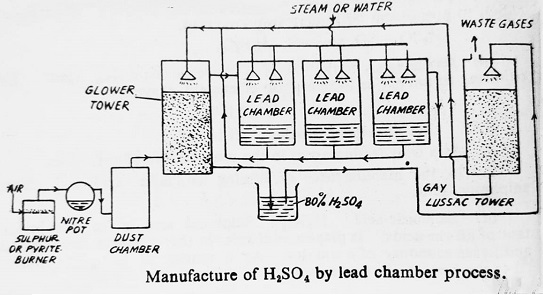

The plant used for the manufacture of sulfuric acid by lead chamber process is indicated in the figure-

In this process, a mixture of SO2, air, steam and oxides of nitrogen is passed through a series of lead chambers. SO2 is oxidized to SO3 by oxides of nitrogen which function as a catalyst. Sulfur trioxide so formed then reacts with steam (H2O) to form sulfuric acid. This acid is referred to as chamber acid and its strength is about 60-70%.

Contact Process:

This is the modern process for the manufacture of sulfuric acid. It is largely used in the production of sulfuric acid these days.

Theory of contact process: The theory underlying the contact process is as under-

(a) Production of sulfur dioxide- Sulfur dioxide is obtained by burning of sulfur powder or iron pyrites in excess of air.

S + O2 ——> SO2

4FeS2 + 11O2 ———> 2Fe2O3 + 8SO2

(b) Conversion of sulfur dioxide into sulfur trioxide- SO2 is oxidized to SO3 by oxygen of air in the presence of platinized asbestos or vanadium pentoxide at 450°C.

2SO2 + O2 ⇌ 2SO3 + 45 kcals.

The above-cited reaction is reversible, exothermic and is accompanied by a decrease in volume. According to Le-Chatelier’s principle, the conditions for maximum yield of sulfur trioxide are as under-

- Low temperature- Low and optimum temperature (450-500°C) is maintained to get maximum yield of SO3.

- High Pressure- A pressure of 2 atmospheres is maintained during the process.

- Use of a catalyst- Platinized asbestos or V2O5 is used as a catalyst to increase the rate of reaction.

- Excess of oxygen- Excess of oxygen should be used during the process.

- Purity of gases- The gases needed like SO2 and O2 should be pure and dry.

(c) Conversion of sulfur trioxide into pyrosulfuric acid- SO3 is absorbed in concentrated H2SO4.

SO3 + H2SO4 ———> H2S2O7 (Pyrosulfuric acid or oleum)

(d) Conversion of H2S2O7 into H2SO4– Sulfuric acid of the desired concentration is obtained by diluting oleum with water.

H2S2O7 + H2O ——-> 2H2SO4

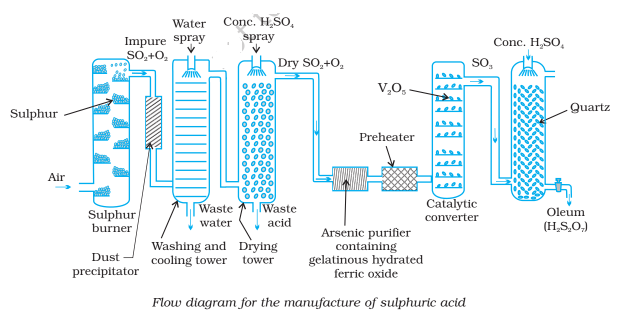

The plant used for the manufacture of sulfuric acid by the contact process is shown in the figure-

In this method, a dry and pure mixture of sulfur dioxide and the air is passed over heated platinized asbestos or vanadium pentoxide as a catalyst in the contact chamber. Sulfur dioxide is converted into sulfur trioxide by the oxygen of the air. Sulfur trioxide so formed is dissolved in concentrated H2SO4 to obtain pyro-sulfuric acid (oleum). It is then diluted with water to get sulfuric acid of any desired concentration.

Uses of Sulfuric Acid:

It is used-

- In the manufacture of fertilizers like (NH4)2SO4 and calcium superphosphate.

- In the manufacture of rayon, paints and pigments.

- In the refining of petroleum products.

- As a dehydrating agent in the laboratory and other research institutes.

- In the extraction of metals like copper and zinc.

- In the manufacture of the acids like HCl, H3PO4, HNO3.

- As an electrolyte in storage batteries and electroplating bath.

- In the manufacture of explosives like TNT, picric acid and dynamite.

- In the tanning of leather in industry.

- As a pickling reagent in enamelling and galvanizing process.

- In the production of a large number of organic compounds.

- In the medicines in the dilute state.

Comments (No)