Table of Contents

Hysteresis:

Many electrical devices have coils wound over materials like iron and the coils carry alternating current. The core is magnetized alternatively in one direction and then in the opposite direction due to the flow of the alternating current. In order to describe how the magnetic flux density B will vary as the magnetizing current is changed, we use a term known as magnetizing field H which is closely related to the magnetizing current I. It is given by-

| H = nI |

The above expression shows the unit of H is A-turns per m. In terms of H, the flux density can be written as-

| B0 = μ0nI = μ0H |

and when filled with some material,

| B = μrB0 = μ0μrnI = μ0μrH or B = μH where μ = μ0μr and μ is called the permeability of the material. |

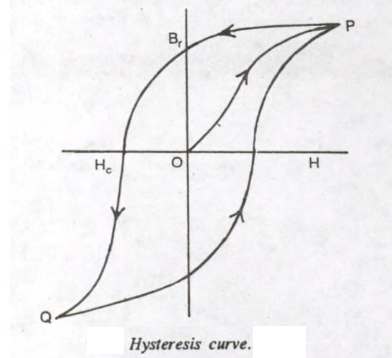

When the magnetizing current I is varied, the magnetizing field H as well as magnetic flux density B vary. For a ferromagnetic material the variation of B with H if represented graphically gives a closed curve of a typical shape. The B-H curve drawn for an entire magnetic cycle for a ferromagnetic material is called a hysteresis loop.

The word hysteresis means delayed, here it is the magnetic induction B which is lagging behind the magnetizing field H.

In connection with the hysteresis loop the following important points must be noted:

- The area of the B-H loop indicates the loss of energy per cycle.

- When H is reduced to zero, B does not become zero. The magnetic induction Br which is left with H is reduced to zero is called remanence or retentivity.

- In order to reduce magnetic induction B to zero, the direction of the magnetizing field is to be reversed and the magnetizing field Hc required to reduce the magnetic flux to zero is called coercive force.

Choice of Magnetic Materials:

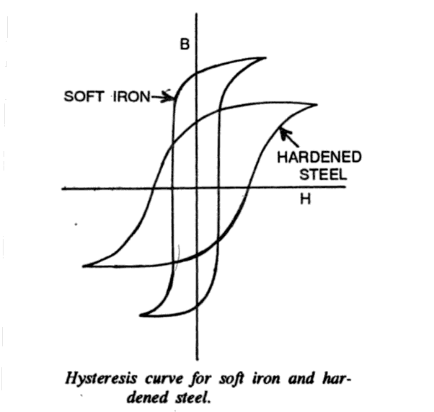

(1) Permanent Magnets- The material for making permanent magnets should have-

- large coercive force (so that magnetism is not easily wiped off by stray fields/ill-treatment).

- high retentivity (so that the magnet is strong).

These requirements are met by hardened steel and alnico (an alloy of Fe, Ni, Co, etc.), hence permanent magnets are made of these materials. It should be noted that, although soft iron has greater retentivity than steel still it is not used for making permanent magnets because a magnet made of soft iron loses magnetism very easily.

(2) Temporary and Electro-Magnets- The material for this purpose should have-

- large initial permeability so that large B is obtained at relatively smaller values of H.

- a smaller coercive force so that magnetism is lost easily.

Materials with narrow BH curves are best suited. Soft iron is, therefore, frequently need for making temporary and electromagnets.

Cores of Transformer and Choke/Magnetic Tape/Telephone Receiver:

Transformer cores and magnetic tapes etc., have to handle alternating currents, hence they must have both hystereses as well as eddy current losses as low as possible. The material should have-

- narrow B-H curve so that hysteresis losses are small.

- high specific resistance so that eddy current losses are small.

- high initial permeability so that large B is obtained for relatively smaller values of H.

Although soft iron is better than steel as it gives low hysteresis losses, still it is not a very good material for transformer cores because of large eddy current losses. Ferrite is a poor conductor and it has all the other qualities of soft iron, therefore ferrite is used for magnetic tapes and high-frequency transformer cores.

Comments (No)